In our industry, we often rely on averages: Average annual HDDs, gallons per delivery, time spent on service calls, etc. Sure, it’s convenient but we should be asking if using averages makes things easier; “I would rather remember one number for the number of stops made per hour than look at every stop.” Interestingly, all those averages are derived from individual data points.

Could focusing on the micro-level make us more efficient without overwhelming us with too many numbers?

Let’s Talk Static vs. Dynamic Reserve:

Consider K-factors. They vary and are (mostly) accurate indicators of consumption per HDD. Similarly, tanks consume fuel at different rates. Lower Ks burn fuel faster in winter than higher ones.

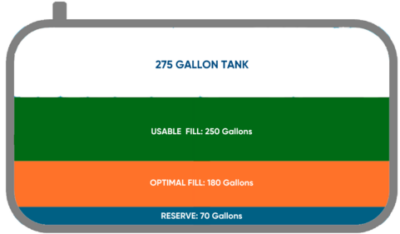

Typically, tanks of the same size have a standard set up. Take a 275-gallon heating oil tank, for instance:

|

Tank Size: 275 gallons Usable: 250 gallons Optimal Fill: 180 gallons Reserve: 70 gallons |

|

It’s likely your tanks will be set up in a similar way. Does it work to have a tank refilled at 70 gallons? I guess so. No major risk of a runout, and that is the top concern of a delivery company – not having runouts.

But where do these 70 gallons come from? Usually, it’s a simple calculation based on typical weather during the month of January and a low K-factor. For example, if there are1000 HDDs in January, that would equal about 32 HDDs/day. With a K-factor of 4, the tank will consume about 8 gallons a day. To allow a 7-to-10-day buffer (in case of delivery issues, sick drivers, bad weather, etc.), you will need 56-80 gallons of reserve. Hence, 70 gallons seems to work – in a Static World.

But what if conditions change? What if the K-factor is higher (most of our clients have an average K factor closer to 8), or there are fewer HDDs? This is where the concept of a Static Reserve falls short.

Enter the Dynamic Tank Reserve:

Imagine if the reserve changed based on the tank and on the HDDs that are forecasted. What if the same rule of “7 to 10 days of reserve” was still in force but adapted dynamically to changing conditions while still providing the security of working to prevent runouts? That would be much better, right?

Dynamic Tank Reserve leverages industry insights, dealer expertise, and tank-specific data to offer a more tailored solution to clients – one that evolves with their needs.